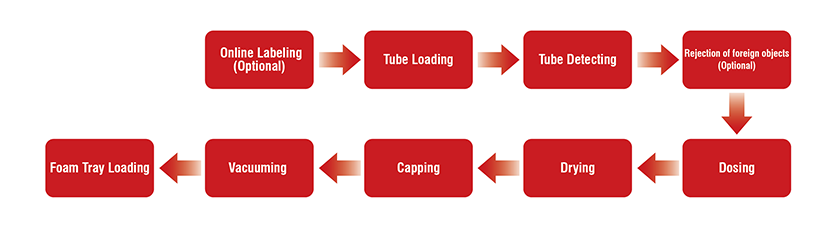

The production line adopts highly integrated modular design, which integrates the core processes of tube loading, liquid addition, drying and vacuuming into independent units, with the volume of each module only 1/3-1/2 of the traditional equipment, and the overall length of the line reaches 2.6 meters (the traditional line length reaches 15-20 meters), which is suitable for the layout of narrow space. The blood collection tube mini assembly line includes stations for loading blood collection tubes, dosing reagents, drying, sealing and capping, vacuuming, and loading trays. With PLC and HMI control, the operation is simple and safe, and only 1-2 workers are needed to run the whole line well. Compared with other manufacturers, our equipment is characterized by compactness and space-saving features, including smaller overall size, higher automation and stability, and lower failure rate and maintenance cost.

The vacuum blood collection tube assembly production line consists of several key components, including a tube forming machine, rubber stopper insertion machine, vacuum generator, cap pressing machine, quality inspection machine, and packaging machine.

The vacuum blood collection tube assembly production line is widely used in hospitals, blood banks, diagnostic laboratories, and other medical facilities. It is an essential piece of equipment for the production of high-quality blood collection tubes.

We warmly welcome all friends from both domestic and oversea markets to cooperate with us in various ways based on mutual benefit, hand in hand to make contributions for the development of medical industry and the health of human beings.

Common Search

Leave your needs, we will get in touch with you as soon as possible!